GoldForce Heavy Duty Brake Components

The heavy transportation industry can be difficult. At GoldForce, we make it easier and more profitable by providing reliable, long-lasting products at an affordable price.

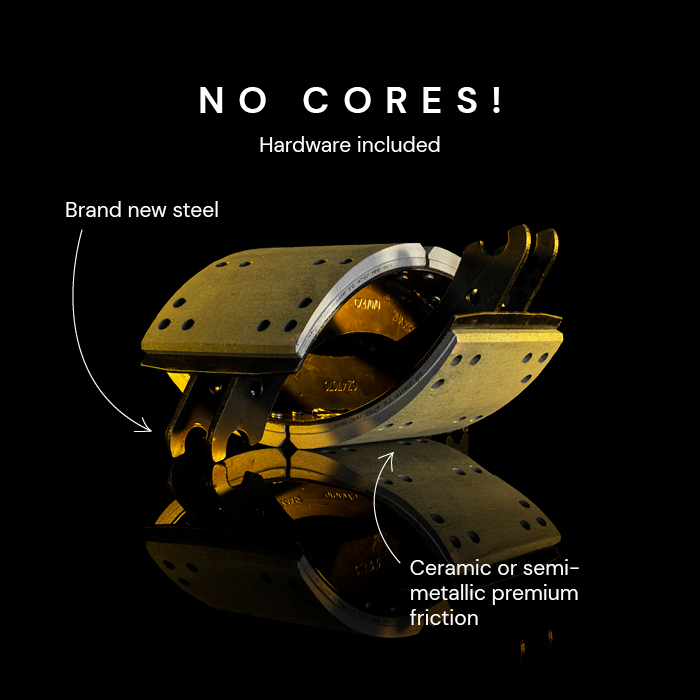

BRAKE WHEEL KITS

This is our Signature

Whether you choose ceramic enhanced or semi-metallic friction, your brakes come mounted on brand new steel, which means NO CORES! Combine premium friction formulas with severe duty hardware and you have fast safe stops, less downtime, and a lower cost-per-mile. Add in excellent corrosion resistance with e-coating to prevent rust jacking, and you’ve got the best wheel kit in the industry.

HEAVY DUTY BRAKE DRUMS

Genuine value with every stop

Our brake drums are made of high carbon grey iron — the best in the industry. Unlike most in the aftermarket, our denser cast cools quicker and lasts longer, because it’s less porous and dissipates heat faster. And don’t forget, every drum is balanced for a smoother ride.

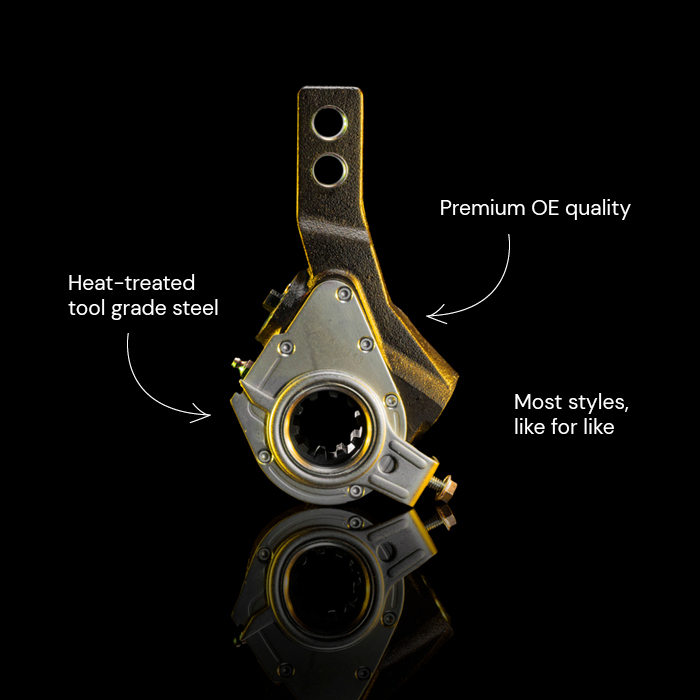

AUTOMATIC SLACK ADJUSTERS

Most styles, like for like

Auto slacks play a crucial role for safe and effective stops. Our adjusters are manufactured to extremely tight OEM tolerances, with heat-treated tool grade steel and quality forgings that ensure dependable performance.

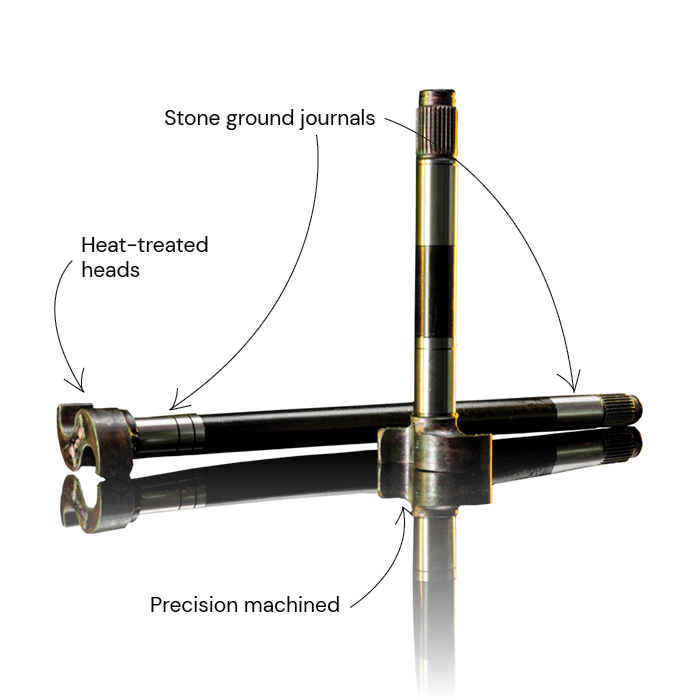

CAMSHAFTS

True excellence

Our cams are unique because the heads are machined instead of just being forged. This means both shoes contact the drum at precisely the same time for balanced stops. Critical wear areas, like head, splines and bearing surfaces, are all heat-treated.

Plus, journals are stone ground for perfect fitment.

Be sure to also install new cam repair kits when you replace the cams. This eliminates excessive play that could otherwise cause brake shoe drag and shorter life. GoldForce precision machined cams and repair kits deliver balanced brakes that stop faster and last longer.

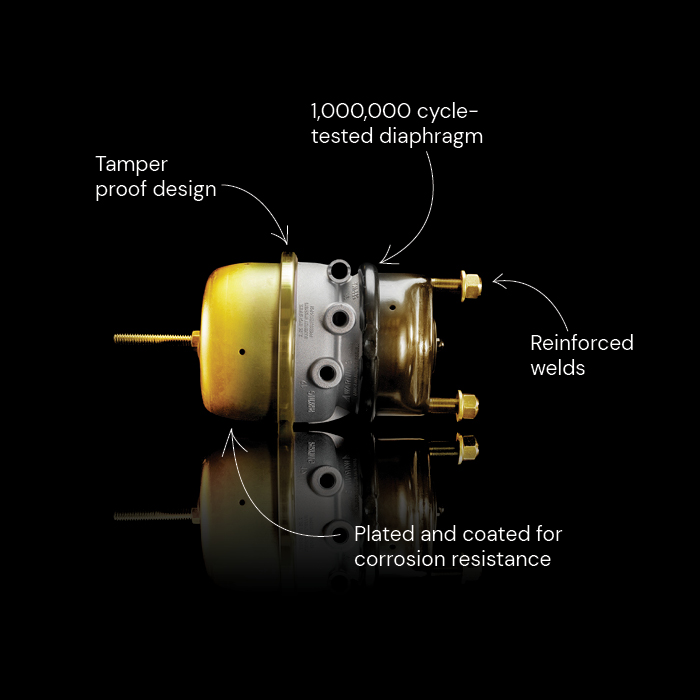

AIR CHAMBERS

Excellent performance, longevity and savings

GoldForce offers premium spring brakes and service chambers, for both drum and disc brake applications. Excellent performance, longevity and savings.

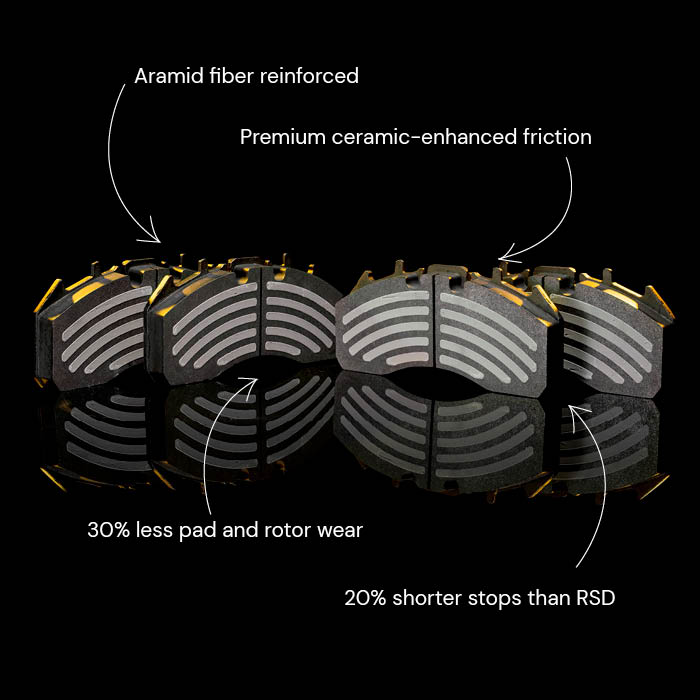

AIR DISC PADS

Safety, without compromise

GoldForce Air Disc Pads provide high torque for fast stops, while beating the federal reduced stopping distance requirements by 22%. Two formulas cover most applications, with Severe Duty units designed to handle extreme situations and just keep on going. Both versions wear less than industry averages, a savings of 30% on pads and rotors.

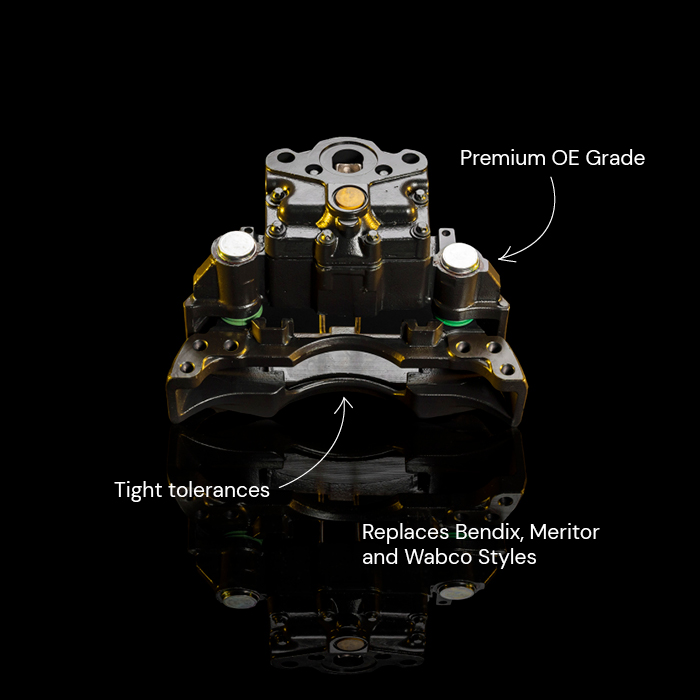

AIR DISC CALIPERS

NO CORE charges, no hassle.

Depending upon the application, your caliper will be all new or remanufactured, but rest assured, always to OE new tolerances. Every unit comes pre-lubed with high temperature grease and seals, plus all new bearings and rails to ensure a trouble-free long life. GoldForce assemblies always come with a carrier, so caliper and pads slide easily without binding or causing brake drag.

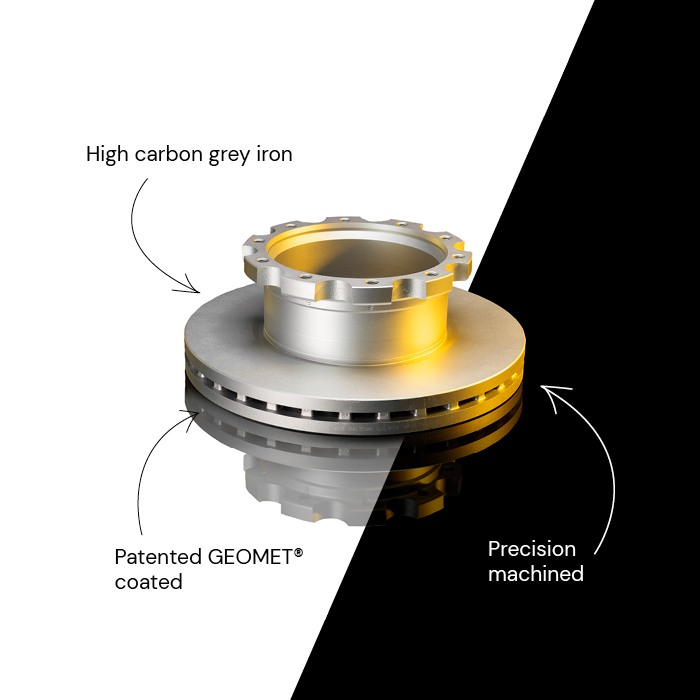

AIR & HYDRAULIC DISC ROTORS

Unmatched performance

Heat is the enemy of brake performance, whether drum or disc, however, discs run much hotter than drums. GoldForce rotors are made with expensive high carbon alloys that dissipate heat much more efficiently than most aftermarket low carbon versions. In addition, patented GEOMET® corrosion protection reduces rust scale on critical areas, like ABS rings and cooling fins, to further improve cooling. A cooler brake that does away with fade, delivers fast reliable stops when you need them. GoldForce discs run cooler, so pads, calipers and rotors all last longer.

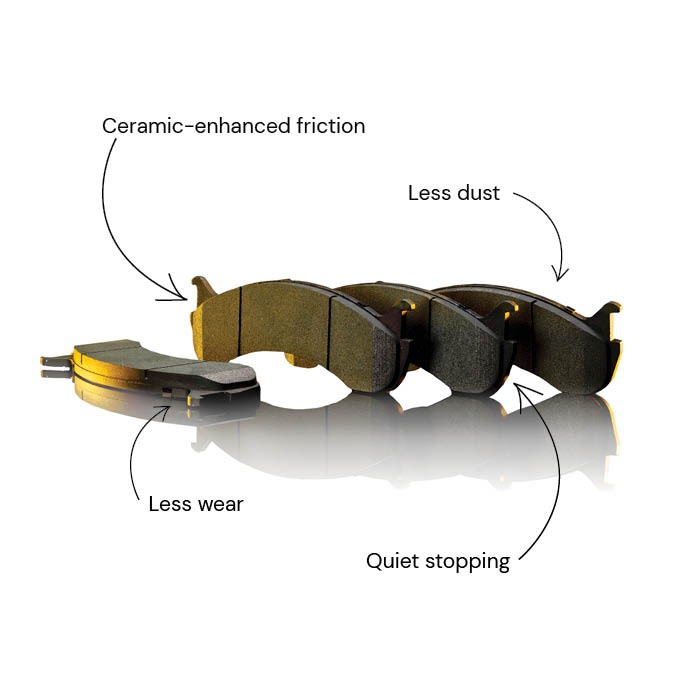

HYDRAULIC DISC PADS

Quiet stops, with less wear

GoldForce Quiet Ride™ ceramic-enhanced disc pads are the perfect solution for school bus and other fleet operators looking for the quietest brakes on the market. In addition to reliable and safe stops, these pads also provide one of the lowest wear rates for both pads and rotors.

For really tough applications, consider Severe Duty. This formula delivers exceptional life in extreme heat, plus stops corrosion caused by winter road chemicals. If you’re looking for the lowest cost per mile, “Severe Duty” is the performer you need.

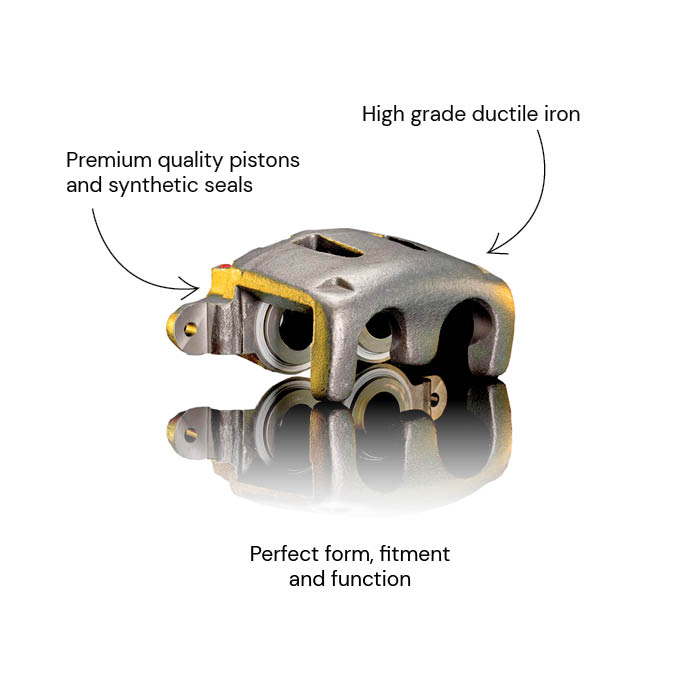

HYDRAULIC DISC CALIPERS

Dependable quality for reasonable prices

GoldForce calipers are precision engineered for perfect form, fit and long life. Plus, most are designed for dual use, so the same part number fits both sides. And the kicker, they’re brand new, so NO CORES!

QUALITY CONTROL

WE KNOW THAT OUR QUALITY REFLECTS HOW YOU WILL PERCEIVE US

GoldForce`s product quality, durability and longevity are what carried our brand name up to today, and provided us with a solid customer base. To maintain these three essential characteristics, we utilize our highly automated processes, rigorous quality control, and the extensive expertise of our engineering team. At every step, our products, which means your products, are controlled and monitored meticulously to make sure you have excellent performance for the long run. To keep up with ever-changing market demand, we continuously invest in new technologies and innovative engineering applications.

We are a NAPA IBS location, not a typical NAPA Store. Our store is inside the city of Kansas City, Missouri. At this location, we deal with vehicles of all sizes. Vactor Vac Trucks, dual axle dump trucks, and Felling trailers, just to list a few. We started using GoldForce back when most of the trucks were drum brakes. The fact that GoldForce was all NEW with no cores was very enticing. We gave them a try, and the city was pleased with the wear of the brake shoes plus, the pricing was a great cost-saving as well. Then came the air disc. We were using the standard Bendix brake pads, K070796. We had an IHC 7600 sewer truck with pad failure. At 13,000 miles, the pads were down to the backing plates. These trucks were all spec’d with ADB22X Bendix systems. They brought Gary in to show us the GoldForce air disc brakes. We decided to try the GFP1369SD severe duty pads. The city has been very satisfied with this product. We are now using GoldForce pads, rotors, and calipers on all heavy-duty vehicles in the fleet. Our Felling trailers are now spec’d with the Wabco Pan 17 brake system, and they are getting GoldForce brakes as well. These trailers are using the GFP1518SD pads. We also have 45 Freightliner 114SD chassis with New Way packer bodies. These are also getting the GoldForce brakes. We are having absolutely no issues with the brakes. Gary is always ready to take our calls and help in any way he can. We have held brake clinics for our NAPA employees and Gary has taught us everything we need to know.

Kathey Williams

Contract Compliance MGR, NAPA IBS KC MO